Step 1: Do You Own a Heat Press?

You need a heat press apply the designs that you cut with a vinyl cutter. If you don’t own a heat press or are looking to upgrade, read our Heat Press Guide: How to Choose a Heat Press for help determining which press is right for you. We also offer a handy chart to compare the features of each heat press.

Heat Press Comparison Chart

Step 2: Learn the Benefits of Using a Vinyl Cutter

A vinyl cutter is used to cut heat transfer vinyl, adhesive vinyl, rhinestone transfers, and twill appliqué materials. When choosing a vinyl cutter, consider what decoration materials are primary to your business. Using a vinyl cutter will give you consistent production and the ability to expand your business potential with HTV and a variety of other materials.

View 5 Reasons Why Your Business Should Use a Vinyl Cutter

Vinyl Cutter Benefits:

- On-Demand Personalization: Most cost-effective for quantities under 25 pieces, including as little as one item.

- Save Time & Money: Use a vinyl cutter to create orders when needed without any additional wait time or costs for shipping.

- Perfect for Sports: A vinyl cutter is ideal to create roster names and numbers for jerseys. You can also cut one or two-color team logos to full uniform personalization.

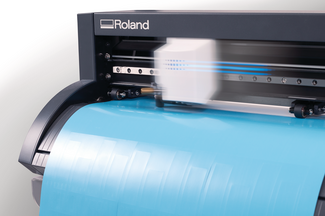

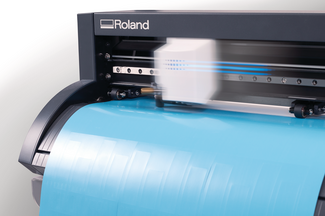

Step 3: Choose a Vinyl Cutter

A vinyl cutter with the ability to cut a wide range of products with accuracy and efficiency is important. Roland and Graphtec are two brands to consider for a quality vinyl cutter with long-lasting performance and production ability. Our vinyl cutter experts are available for an online demo with either brand to help you be sure you’re investing in the right equipment. Use our Vinyl Cutter Comparison Chart to quickly view the features of each vinyl cutter.

Schedule Online Vinyl Cutter Demo

Vinyl Cutter Comparison Chart

Step 4: Determine What Design Software to Use

You may already have experience with Corel® or Adobe® software; if not, consider one of the following options for ready-to-use artwork:

|

Roland DG GS-24

|

|

Graphtec CE7000-60

|

|

Step 5: Stock Heat Transfer Vinyl

Choosing heat transfer vinyl is typically based on the type of fabric or garment being decorated. A vinyl cutter will allow you to stock varying HTV so you’re prepared for any job. Consider these tips when adding materials to use with your vinyl cutter.

Be aware of polyester fabrics. Some dyes can bleed through heat transfer materials. When decorating polyester fabrics, select CAD-CUT® Thermo-FILM® to help inhibit dye migration.

Nylon can be a difficult fabric for heat application. Sometimes nylon is chemically coated to prevent waterproofing or sun exposure, creating a barrier for heat adhesion. Be sure to check garment specifications before purchasing decoration materials.

With any HTV, start with basic colors. White, black, red, royal, navy, and athletic gold are top sellers in any market and ideal stock in any material.

For help with selecting the best materials for your project, review this chart of popular heat transfer material and fabric combinations.

| Popular Heat Transfer Materials and Fabric Combinations |

| Best for |

Sports/

Uniforms |

Lightweight Fabrics |

Stretch Fabrics |

Special Effects |

| CAD-CUT® Heat Transfer Material |

Best HTV:

Thermo-FILM® |

Best HTV:

CAD-CUT® UltraWeed™; |

Best HTV:

Premium Plus™ |

Best HTV:

Glitter Flake™ |

| Benefits |

Benefits:

Inhibits dye migration |

Benefits:

Great for T-shirts |

Benefits:

Great for performance wear |

Benefits:

Hottest selling special effect material |

| Suggested Fabric Types |

Suggested Fabric Types:

Polyester |

Suggested Fabric Types:

Cotton |

Suggested Fabric Types:

Lycra®/

Spandex |

Suggested Fabric Types:

Cotton or Polyester |

View All Material & Fabric Combinations Chart